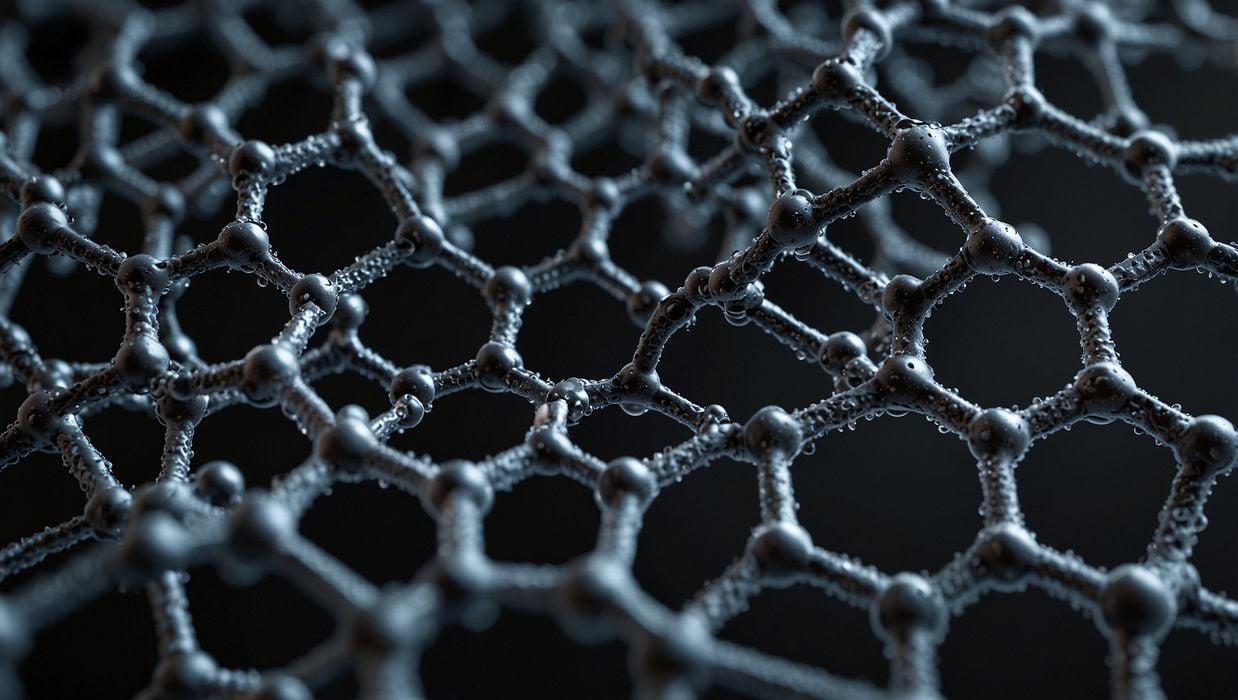

In the effort to adopt more sustainable industrial practices, advanced materials such as pristine graphene are making a significant impact. Pristine graphene stands out for its purity and structure, making it a critical component in the innovation of sustainable manufacturing. With outstanding strength, conductivity, and lightness, it is helping to transform processes across a range of industries. The points below highlight five important contributions pristine graphene is making to sustainable manufacturing.

Increasing Material Efficiency

Manufacturers benefit from pristine graphene’s remarkable strength-to-weight ratio, which enables the production of strong yet lightweight components. By using less raw material without compromising on durability, companies reduce waste, lower production costs, and conserve valuable resources. This is particularly relevant in sectors such as automotive and aerospace, where lighter parts contribute to improved fuel efficiency and a reduced environmental footprint, supporting broader sustainability initiatives.

Supporting Renewable Energy Development

The high conductivity and stability of pristine graphene have proven valuable in the development of modern renewable energy technologies. Solar panels enhanced with graphene are more efficient and effective even under low light. Furthermore, batteries and supercapacitors that incorporate graphene can store more energy, charge more quickly, and offer greater durability. These properties are particularly useful as the world relies more on renewable resources like wind and solar power, supporting a steady transition to greener energy grids.

Lowering Carbon Emissions

Using graphene in manufacturing often leads to reduced energy usage. Its excellent thermal and electrical conductivity means that less energy is required during both the production phase and the operation of the final product. For example, electronics built with graphene use less electricity and still deliver high performance, which helps lower greenhouse gas emissions throughout their lifecycle. By embracing these approaches, industries can reduce their total environmental impact and move toward more sustainable operations.

Improving Water Purification and Management

Pristine graphene is playing a growing role in efforts to address water scarcity around the world. Graphene membranes excel at filtering and desalinating water, delivering clean water more efficiently and cost-effectively compared to many traditional technologies. For instance, Dr. Membrane Hossain has developed a graphene oxide membrane specifically designed for seawater desalination. This system allows water molecules to pass while preventing salts and other impurities, offering an innovative solution for communities in need of reliable clean water.

Creating More Durable, Long-Lasting Products

Incorporating graphene into coatings and composites leads to longer-lasting products across industries, from vehicles to electronics. Graphene provides resistance to corrosion, abrasion, and chemical wear, helping components maintain their function over time. As a result, manufacturers can reduce the frequency of replacements and repairs. This improvement in product lifespan supports environmental goals by cutting down on industrial waste and promoting a more sustainable, circular approach to manufacturing.

Kjirstin Breure, CEO of HydroGraph Clean Power, has played a leading role in advancing sustainable technology through her work. Kjirstin Breure is a dedicated leader committed to introducing new, sustainable engineering solutions to the market. Pristine graphene presents a responsible choice for industries seeking efficiency and environmental stewardship, supporting a future where innovation and sustainability go hand in hand.