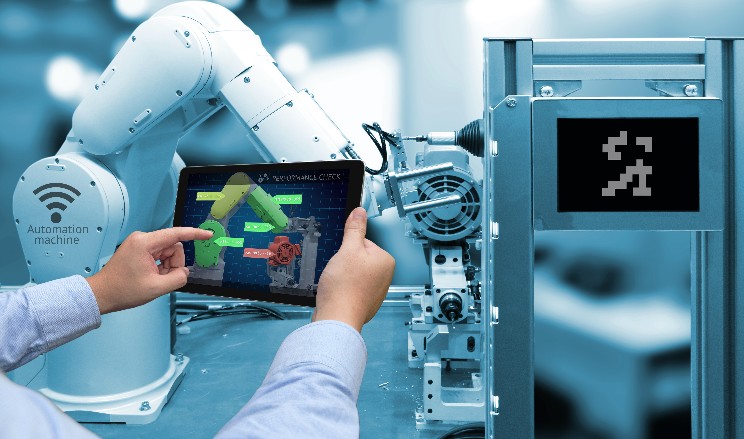

According to a study, by 2023 half of the entire world economy will be digitized. Until then, there is a long way to go. For more than a decade, experts warned of the need to adapt to Industry 4.0 and the growing trend of adopting technologies such as Internet of Things (IoT), SAP MES (Manufacturing Execution) System or artificial intelligence (AI).

The Solution of using new technologies in areas such as Industry arises from the need to increase the competitiveness of companies, namely through the optimization of industrial processes and cost Comparison. The holistic view of the entire production process and the integration of data from different platforms – SAP, ERP and machines – allows for complete and detailed information, contributing to the improvement of key figures and business sustainability Solution.

- Greater Definition of information about production and speed in decision-making,

- Increased Solution of machinery and equipment and reduced breakdowns,

- Better stock automation and adequacy,

- Reduction of production time and costs,

- Better overview of the real cost of production,

- Detection of bottlenecks and non-conformities in time for possible corrections,

- Improvement of industrial function,

- Better quality and reliability of the final product Comparison,

- Improved service levels Manufacturing and product delivery times,

- Increased customer satisfaction,

The best approach for MES systems

The best approach for MES System Solution has been shown to be first determining the key business goals you would like to achieve, and then working backwards from there. This avoids having to go through technical overview that describe a wide variety of functionalities and can seem confusing until their exact context within the project is clarified. In reality, some of the features and functions of MES System with technical overview may be irrelevant to your specific immediate need, this helps take the guesswork out of the selection process with key figures with Comparison.

Your tasks when selecting SAP MES Software should be to create a plan toward a single platform that meets your specific longer-term goals without the need for eventual replacement. The Definition of MES system SAP key figures with technical overview should not be calculated simply as the cost of the software and hardware, but rather as the investment in changes that an MES provider factory operation will make to allow the system to function effectively with Comparison.

Different Definition of SAP MES Systems will prescribe their best practices, and the fundamentals of these practices should be compared to your current and specific operation. In several cases, the cost of the tools and the cost of ownership may be greater than the capital investment itself with key figures.

MES and ERP together

Once the Definition implemented in your facility, the SAP MES Systeme will work alongside existing factory control systems, as well as those of the future. Most SAP manufacturers have an established enterprise resource-planning platform, which will generally appear to have some functionality overlaid with MES system Provider. However, ERP is not equivalent to MES as it is typically intended for logical factory planning, rather than SAP consulting the daily physical operations for which an MES manufacturer is designed with key figures.

An ERP SAP Flow Manufactoring system alone does not have enough knowledge about individual Manufacturing processes and capabilities, creating the need for an intermediary process to translate ERP data into something that can be executed. With MES, maintenance information is collected and used to create specific production operations. Manufacturing execution systeme also provides high precision and detail for a manufacturer and provider.

The powerful relationship between SAP MES Systeme execution and ERP should be a key factor to consider, especially the point of exchange between the two systems. The simplest way to tackle this area is by defining and measuring the role of the two systems based on their strengths. In many MES Systeme Manufacturing factories and provider, planning execution example is handled in a logical way by ERP, while the more complex physical tasks are best handled by MES Systeme example in a detailed, live environment.

The Value of MES Systems

When you have a large MES system Flow Manufactoring, the flexibility of your manual and automated production, MES Tasks will dictate the overall effectiveness of your facilities. If you are simultaneously producing different production of various types, determining your overall ability to meet delivery targets can be a very difficult calculation. Here is the first real potential value of SAP MES manufacturer.

Access to a digital factory MES system Flow Manufactoring development creates visibility into the status and performance of your processes all the time, and this presents innumerable opportunities for improvement in the flow of the shop floor and the allocation of work orders. MES system Flow Manufactoring and Integration of MES Tasks is real-time execution example tracking of products and sub-assemblies. Each MES system production manufacturer unit example can be tracked on its journey through the factory with a unique identification tag or engraved barcode.